Wastewater Facilities

T-TSA owns, operates and maintains the Truckee River Interceptor (TRI) and Water Reclamation Plant (WRP). The TRI conveys wastewater from Tahoe City to the WRP in Martis Valley, east of the town of Truckee, California. The TRI collects flows from the five member districts that comprise T-TSA. The reinforced concrete pipe sewer is approximately 17 miles and varies in diameter from 18 inches to 42 inches.

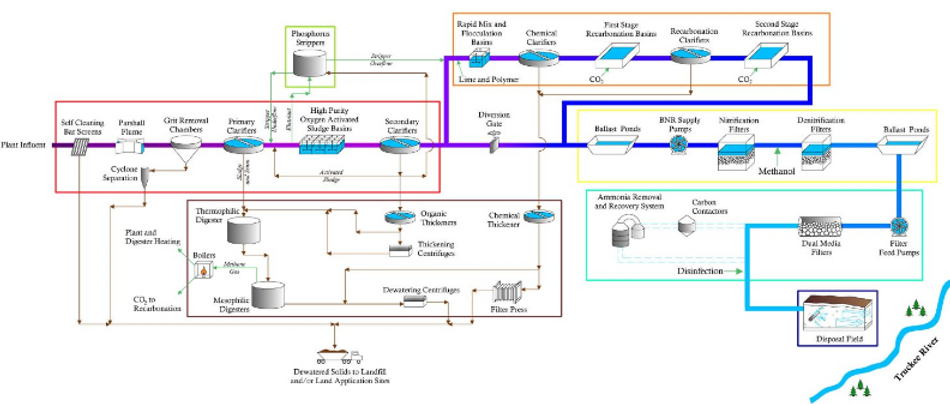

Wastewater treatment occurs at the WRP. The regional facility was designed to treat the sewage of its five member districts that are located in the Tahoe and Truckee River Basins. Through a series of biological, chemical and physical processes, the wastewater is purified to a degree where surface and ground water integrity is protected.

The sequence of treatment units is comprised of seven major sections:

Conventional Treatment

Conventional treatment is used to enhance mainstream water quality by a reduction in the particulate and soluble fractions of organic and inorganic compounds. The processes involved consist of screening, grit removal, primary treatment, high purity oxygen activated sludge secondary treatment, and advanced biological phosphorus removal.

Advanced Biological Phosphorus Removal (Phostrip™)

Phostrip™ is an integral part of the high purity oxygen activated sludge process. Its function is to remove mainstream phosphorus and concentrate this element into a rich sidestream (stripper overflow). This sidestream is normally the only water to be chemically treated. Typically, the bulk of the secondary effluent bypasses the chemical treatment section.

Chemical Treatment

The phosphorus-rich sidestream is subjected to high pH lime treatment. The lime reacts with soluble phosphorus forming a relatively insoluble complex of calcium hydroxylapatite. Subsequent steps in chemical treatment consist of two stages of recarbonation, using carbon dioxide, separated by clarification. The first recarbonation process involves calcium polishing while the second addresses pH control. The chemically treated water is then blended with the bypassed secondary effluent upstream of the ballast ponds.

Biological Nitrogen Removal (BNR)

The cornerstone of the most recent major expansion project is the BNR system, which includes submerged biologically aerated nitrification and denitrification filters. Because of its ability to biologically remove most of the nitrogen species in the water, the BNR process is essential to achieving compliance with the rigorous discharge requirements and addressing concerns of downstream users of the Truckee River.

Advanced Wastewater Treatment

These processes are designed to reduce suspended solids, decrease refractory organics, further lower the nitrogen level, and destruct/inactivate pathogens. These goals are achieved by dual media filtration, activated carbon adsorption, ion exchange, and disinfection, respectively. The activated carbon adsorption and the ion exchange process are only used intermittently, as water quality dictates.

Land Disposal of Effluent

The last step in the treatment process is to apply the final effluent to the soil via a subsurface percolation system. The effluent is further polished as it percolates through the ground.

Solids Handling

As a byproduct of treating the wastewater, inorganic and organic sludges are generated. These sludges are thickened prior to processing further. Organic sludges are digested for the purpose of stabilizing the material prior to ultimate dewatering and disposal. Through proper blending and conditioning, certain sludges that are produced may be put to beneficial reuse.